Blasting Glass Beads For Metal Cleaning And Polishing: Aluminum & Stainless Steel

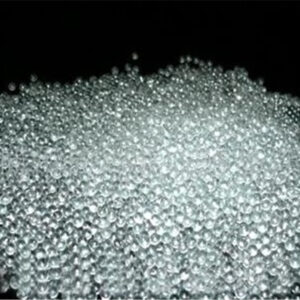

Shot blasting glass beads are glass beads used for surface treatment of industrial parts, made of non-alkaline soda calcium silicate, with certain hardness and elasticity. The particle size is generally between 45 μm and 1000 μm, and the microhardness is generally between 500 and 550Kgf/mm².

Surface-treated shot-peened glass beads have certain mechanical hardness, strength, and strong chemical stability. It is suitable for cleaning and polishing the burrs and dirt on the surface of various molds, so that the processed parts have a good finish and prolong the service life.

Main Physical Indicators of Glass Beads:

1. Appearance: round, transparent, no obvious bubbles and impurities

2. Particle size between 45um and 1000um

3. Softening point: 710-730 ° C

4. Density: 2.4-2.6g/cm3

5. Rounding rate: industrial shot peening beads ≥ 90%

6. Refractive index: ≥ 1.5

7. Hardness: Mohs 6-8

8. The main ingredients: sodium-calcium glass composition

9. Metal: Aluminum & Stainless Steel

The Advantage of Blasting Glass Beads For Metal Cleaning and Polishing (Aluminum & Stainless Steel)

1. It has a certain mechanical strength, hardness and sufficient elasticity, can be used repeatedly for several times, the effect is the same, and it is not easy to break;

2. The particle size of the glass beads is uniform, and the brightness coefficient of the sandblasting machine remains uniform after spraying, and it is not easy to leave watermarks;

3. Good chemical stability, will not pollute processed metals (aluminum & stainless steel);

4. The surface is smooth, the finish is good, and the mechanical precision of the workpiece is not damaged;

5. High rounding rate and no impurities. Its detection methods are advanced, and the product quality is superior, which meets the requirements of international and domestic standards.

The Specification of Blasting Glass Beads for Metal Cleaning and Polishing

| Type | Size(μm) | Mesh |

| #30 | 850-425 | 20-40 |

| #60 | 600-300 | 30-50 |

| #80 | 425-212 | 40-70 |

| #100 | 212-150 | 70-100 |

| #120 | 212-150 | 70-100 |

| #150 | 150-106 | 100-150 |

| #180 | 106-75 | 150-200 |

| #220 | 106-53 | 150-270 |

| #280 | 75-45 | 200-325 |

| #320 | 325max | / |

The Application of Glass Beads Media for Metal Cleaning and Polishing

1. Matte surface treatment of stainless steel and aluminum products.

2. Cleaning of stamping, forging, rubber, plastic, metal casting, extrusion and other molds.

3. It can eliminate the tensile stress of various parts, increase the fatigue life, and improve the stress resistance and corrosion resistance. Such as aircraft engine turbines, blades, shafts, landing gear, various springs, gear hydraulics, etc.

4. Clean and remove waste edge burrs before tinning integrated circuit boards and sealing tubes.

5. Clear the blockage in the cylinder and piston.

6. Shot blasting and finishing of medical equipment, textile machinery, food machinery and various hardware products.

7. Cleaning of coils, brush rotors and other components during motor maintenance.

8. Cleaning of various metal pipes and non-ferrous metal precision castings to remove burr residues.

9. Derusting, deoxidizing, polishing and thickening of various parts inside and outside, and removing stress.

10. Polishing of various jewelry, watches, lamps, cosmetics, and glasses accessories.